How To Start Textile Screen Printing Business | SkillsAndTech

Textile screen printing is the process of applying color to the fabric in definite patterns or designs. In properly printed fabrics the color is bonded with the fiber, so as to resist washing and friction. It refers to the production of designs of any kind that could not be made on textile fabrics by normal weaving/knitting techniques.

This type of printing is generally done on finished fabrics, curtains, clothes, ladies dress materials, bed sheets, bed covers, fabric for children garments, gents shirts, etc. to improve its attractiveness, marketability, etc. Nowadays, you will find a lot of upgraded machinery in the market. The process is not complex. Technical guidance about the printing is also available.

See Also: How To Start Tracksuit Making Business

Table of Contents

Understand the Market Potential

Nowadays, textile screen printing offers ample innovation and creativity. It is playing a major role in the printing industry because of the availability of advanced screen printing machines, UV technology coupled with the availability of innovative special effects inks.

See Also: How to Structure a Franchise Business

Screen printing is now quicker, cheaper, produces better quality images, and offers a number of special applications. This type of printing business has a good market potential both in the domestic and export market.

Make your Business Legal

In starting a small and medium-scale textile screen printing unit, you will need to obtain the following registrations and licenses.

- Business registration with ROC

- Trade License from Municipal Authority

- GST Registration

- Udyog Aadhaar MSME Registration

- NOC from Pollution Control Board

- IEC Code for export.

Machinery & Raw Materials

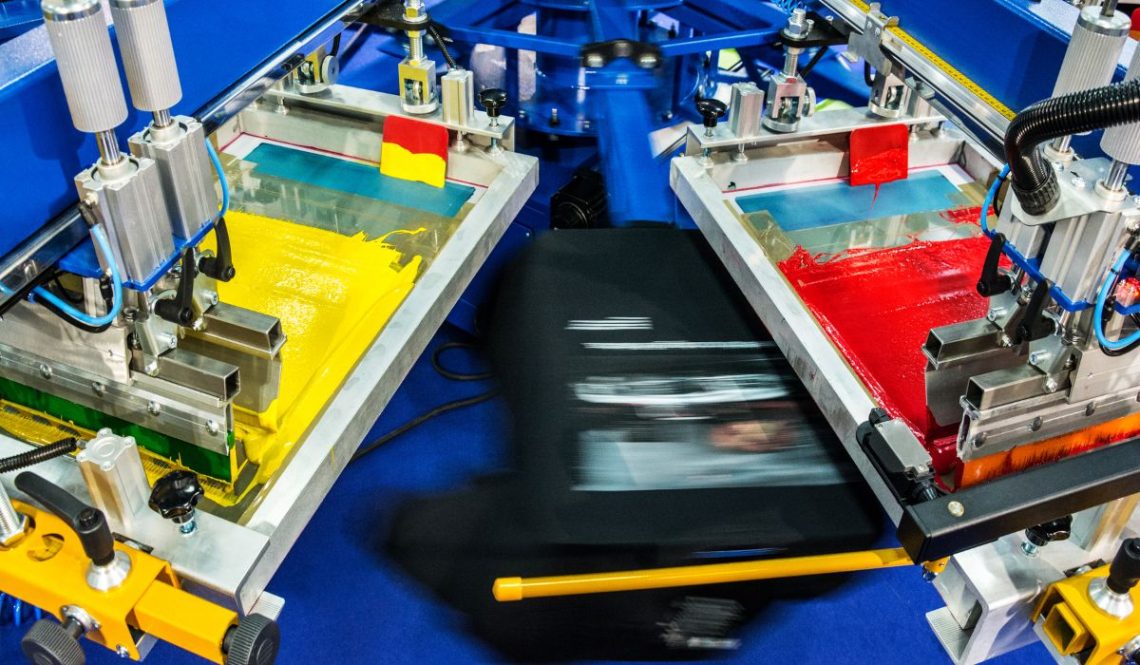

In the last decade, from a predominantly manual printing process, there has been a big shift to semi-automatic and now fully automatic printing machines.

- Printing Table with AC Top

- Rubber squeezers

- Cottage steamer

- Open width jigger

- Cylinder drying machine

- Baby boiler

- Washroom trolleys

- Dye paste stirrer

- Weighing balance (Dial model)

You can also set up an automatic and large-scale textile screen printing unit. These types of machines allow versatile sizes and quality of fabrics to print.

See Also: How To Start Automobile Spare Parts Making Business

Any types of fabric including sarees, clothes, bedsheets, and textiles are the raw material for this type of printing unit.

Cost of Starting Textile Screen Printing Business

The startup investment will mainly depend on the size of your printing unit. However, on a small scale, one needs to invest a minimum of Rs. 5 Lacs to start a textile screen printing business.

See Also: How To Start Talcum Powder Making Business

If you are short in funds, one can approach banks and private investors for startup funding for your textile screen printing business. It is worth mentioning here, that a professionally documented business project plan will be a key factor in getting approval for funds from banks.

Learn Textile Screen Printing Process

Different steps involved in the printing process are the preparation of printing paste, the printing of fabric, fixation of dyestuff by curing/steaming, washing off, calendering, folding, and packing. Scoured and bleached cotton fabric as obtained from dealers is inspected to remove any objectionable faults and stretched evenly on the printing table.

See Also: How To Attach Your Car To Ola Cabs

Screens containing the designs are placed over the table and the dye paste is pressed over the screen by means of a rubber squeezer.

The selection of dyes and gums depends on the construction of basic cloth to be printed and their end-users. After printing, the printed clothes are cured or steamed for the fixation of the color.

Later, the printed material is thoroughly washed to remove loose dyestuff. Then, it is calendered, folded, and packed for delivery.

See Also: How To Start Hair Band Making Manufacturing Business

With an automatic textile screen printing machine, you will get more consistent and decent printing quality with a large quantity output.

7 Comments

Pingback:

Pingback:

Pingback:

Pingback:

Pingback:

Pingback:

Pingback: